Bodies

Bodies are any physical object that is not represented as a boundary condition. They can be water, debris, structures, etc., but not, for instance, a moving velocity boundary condition.

This section discusses the setup of bodies in the model.

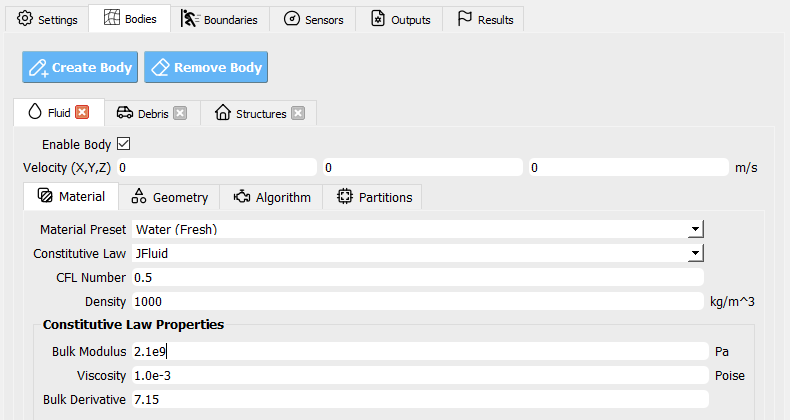

Material

The material panel is where you set parameters related to the material properties / constitutive law of the bodies in the simulation.

Water, plastic, concrete, sand, steel, clay, rubber, etc. are some of the material presets that can be used to define the bodies. Constitutive laws are selected based on the material preset with appropriate initial values for the material properties. Constitutive laws are used to define the material behavior under different loading conditions. Options include:

Isotropic Fluid with Viscous Shear Stress / J-Fluid: This is used to define a basic Newtonian fluid. The material properties include density, bulk modulus, derivative of the bulk modulus with respect to pressure, and dynamic viscosity.

Fixed-Corotated / Neo-Hookean: This is used to define solid hyperelastic material behavior under large strains. The material properties include Young’s modulus, Poisson’s ratio, and density.

Drucker-Prager: This is used to define solid/granular material behavior under large strains. The material properties include Young’s modulus, Poisson’s ratio, density, and the Drucker-Prager parameters.

Non-Associative Cam-Clay: This is used to define solid/granular material behavior under large strains. The material properties include Young’s modulus, Poisson’s ratio, density, and the Non-Associative Cam-Clay parameters.

Material properties are defined in the Material tab and are specific to the chosen constitutive law/material model. The material properties include:

Density: This refers to the density of the material. This is defined in terms of the mass per unit volume. The units are generally in kg/m3.

Young’s Modulus: This refers to the stiffness of the material. This is defined in terms of the force per unit area. The units are generally in Pa.

Poisson’s Ratio: This refers to the ratio of the lateral strain to the longitudinal strain. This is a dimensionless quantity.

Bulk Modulus: This refers to the measure of the material’s resistance to uniform compression. This is defined in terms of the force per unit area. The units are generally in Pa.

Viscosity: This refers to the measure of the material’s resistance to flow. This is defined in terms of the force per unit area. The units are generally in Pa * sec.

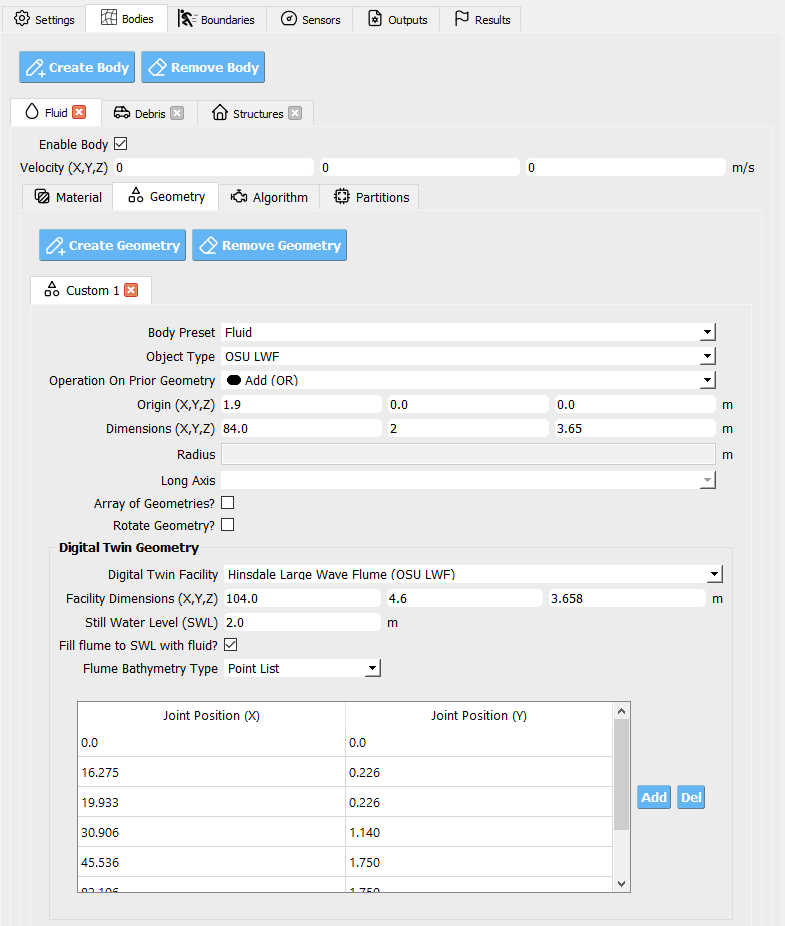

Geometries

Geometries is a collection of geometry tabs which you can add and delete using the corresponding buttons.

Each geometry is defined by an object (e.g., box, sphere, …) and object-specific parameters for position and size. When defining each geometry, you also select an operation that composes it in order with the previously listed geometry tabs:

Add — union with the current aggregate

Subtract — remove this shape from the aggregate

Intersection — keep only the overlap with the aggregate

Difference — boolean difference (variant of subtract, if provided)

Tip

Use small, simple primitives first, then refine with additional tabs. The final geometry is the ordered composition of all rows in the list.

Note

If two tabs produce unexpected results, check their order, coordinate frames, and dimensions. Composition is order-dependent.

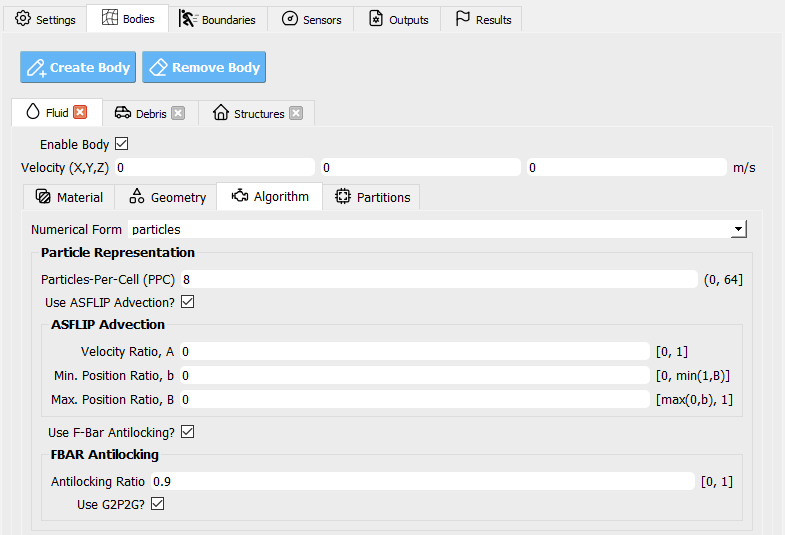

Algorithm

This advanced panel selects the numerical options used to simulate the material body.

Setting |

What it does |

Guidance |

|---|---|---|

F-Bar Antilocking |

Relieves volumetric locking artifacts in MPM to improve near-incompressible behavior and stress accuracy. |

Enable for materials prone to locking; verify stability. |

ASFLIP |

Affine Separable FLIP advection scheme that reduces grid–particle transfer null-space errors, typically lowering artificial damping and improving debris–debris contact behavior. |

Often beneficial for highly dynamic flows. |

PPC (Particles-Per-Cell) |

Sets the number of particles sampled per grid cell at body creation. |

Higher PPC → better resolution but higher cost. |

Important

These options target expert users. Changing them can materially affect stability, accuracy, and performance. Prefer defaults unless you have validation data or a clear need.

Tip

If you increase PPC, consider refining the grid-cell size and revisiting time-step limits (CFL) to maintain stability and accuracy.

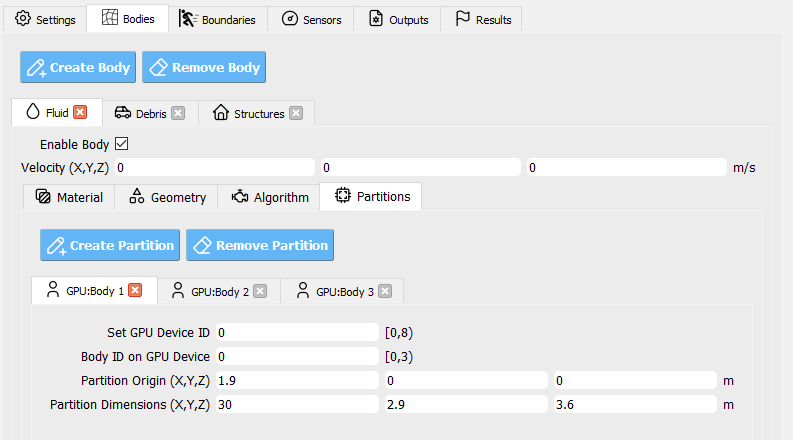

Partitions

This is an advanced configuration used to distribute a body across available hardware partitions (e.g., GPUs or compute nodes) for parallel computation.

Define a set of partitions; each partition is assigned a Model ID and a GPU/Device ID, allowing multiple bodies per device if desired.

Each partition specifies a spatial domain that constrains where particles for this body may be generated or migrated.

The union of all partitions should reconstruct the full body without gaps; optional overlaps can improve load transitions (if supported).

Warning

Misaligned or disjoint domains can cause missing particles or load imbalance. Verify that partitions cover the full body and align with the global grid.

Tip

Partition optimization can significantly improve load balancing and throughput. Start with a single partition per device, inspect utilization, then refine domains to equalize work across devices.

Note

Major changes here are recommended only for users familiar with the target cluster’s hardware and scheduling behavior.