4.2. Site Response Analysis with Spatial Variability

This page shows two examples of how to incorporate spatial variability into UQ analysis by using various special materials, namely ElasticIsotropic, PM4Sand, and PDMY03, in the Site Response option under the EVENT tab.

4.2.1. Problem Statement

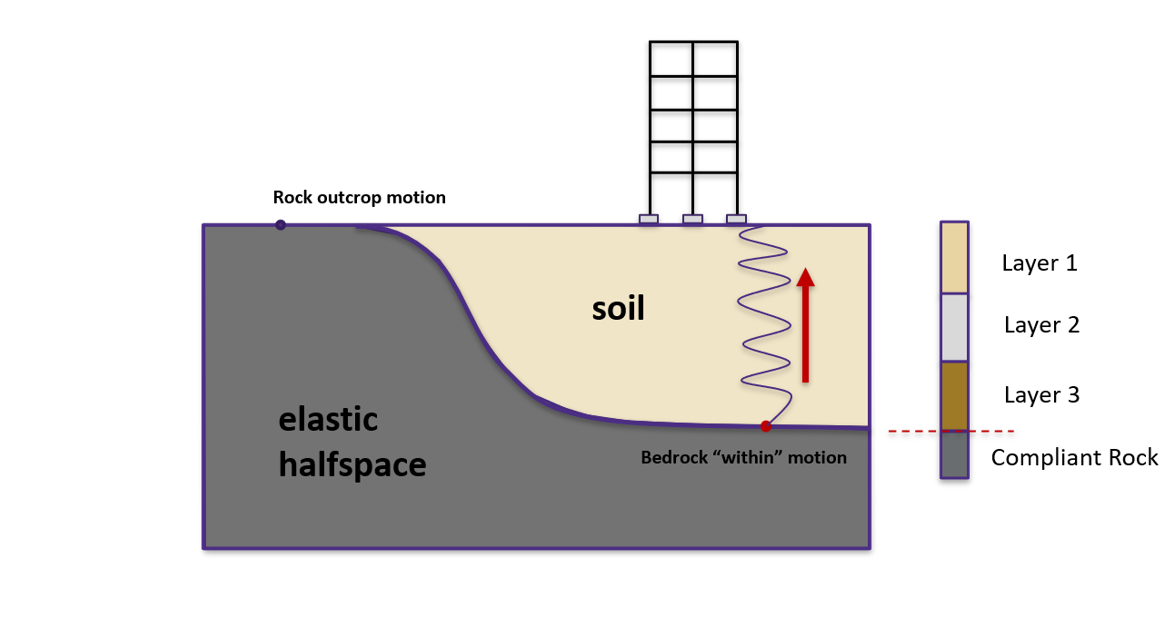

Site response analysis is commonly performed to analyze the propagation of seismic waves through soil. As shown in the below figure, one-dimensional response analyses, as a simplified method, assume that all boundaries are horizontal and that the response of a soil deposit is predominately caused by SH-waves propagating vertically from the underlying bedrock. Ground surface response is usually the major output from these analyses, together with profile plots such as peak horizontal acceleration along the soil profile. When liquefiable soils are presenting, maximum shear strain and excess pore pressure ratio plots are also important.

Fig. 4.2.1.1 Simplified 1D site response analysis (courtesy of Prof. Pedro Arduino)

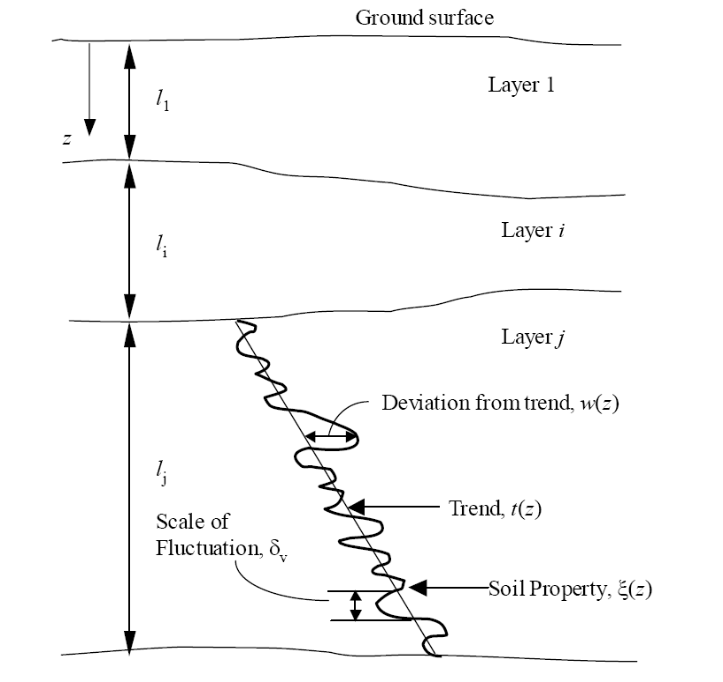

In real-world conditions, the physical properties of soils vary from place to place within a soil deposit due to varying geologic formation and loading histories such as sedimentation, erosion, transportation, and weathering processes. This spatial variability in the soil properties cannot be simply described by a mean and variance, as commonly adopted in UQ analyses since the estimation of the two statistic values does not account for the spatial variation of the soil property data in the soil profile. Spatial variability is often modeled using two separated components: a known deterministic trend and a residual variability about the trend. These components are illustrated below.

A summary of the random field preparation procedure for the site response event analysis is summarized here:

Generate mean field using mean target soil property, e.g., relative density (Dr) or shear wave velocity (Vs)

Generate Gaussian random field for target soil property using Gauss1D.py with mean = 0.0 and \(\sigma\) = 1.0

Interpolate Gaussian field to FEM mesh

Combine the mean (trend) field and Gaussian (residual variability) field to obtain a stochastic field

Generate material input for site response analysis based on predefined model calibration methods

Perform site response analysis using the randomized material input and obtain acceleration response at the surface of the soil column for subsequent UQ analysis

Note

Currently, only 2D plain-strain materials (including PDMY03 and ElasticIsotropic) are supported when using random fields. Therefore, 1-component motions are required.

4.2.2. General Workflow for Global Sensitivity Analysis

In a global sensitivity analysis, the user wishes to understand what is the influence of the individual random variables on the quantities of interest. This is typically done before the user launches large-scale forward uncertainty problems in order to limit the number of random variables used so as to limit the number of simulations performed.

Note

For this problem, we will limit the response quantities of interest to the following six quantities. Peak Roof displacement in 1 and 2 directions, root mean square (RMS) accelerations in 1 and 2 directions, Peak BAse shear and moments in 1 and 2 directions.

To perform a Global Sensitivity analysis the user would perform the following steps:

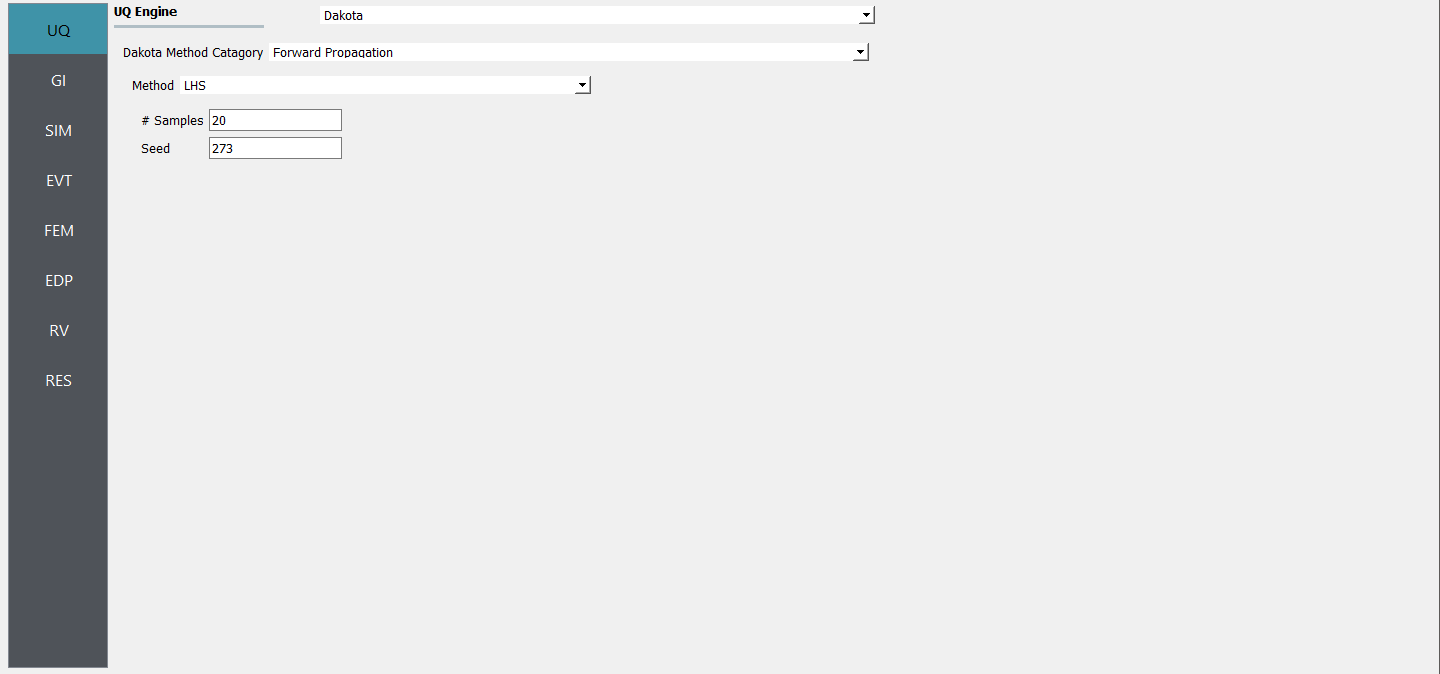

1. Start the application and the UQ Selection will be highlighted. In the panel for the UQ selection, keep the UQ engine as that selected, i.e. Dakota. From the UQ Method Category drop-down menu select Sensitivity Analysis, Keeping the method as LHS (Latin Hypercube). Change the # Samples to 20 and the Seed to 273 as shown in the figure. The seed specification allows a user to obtain repeatable results from multiple runs.

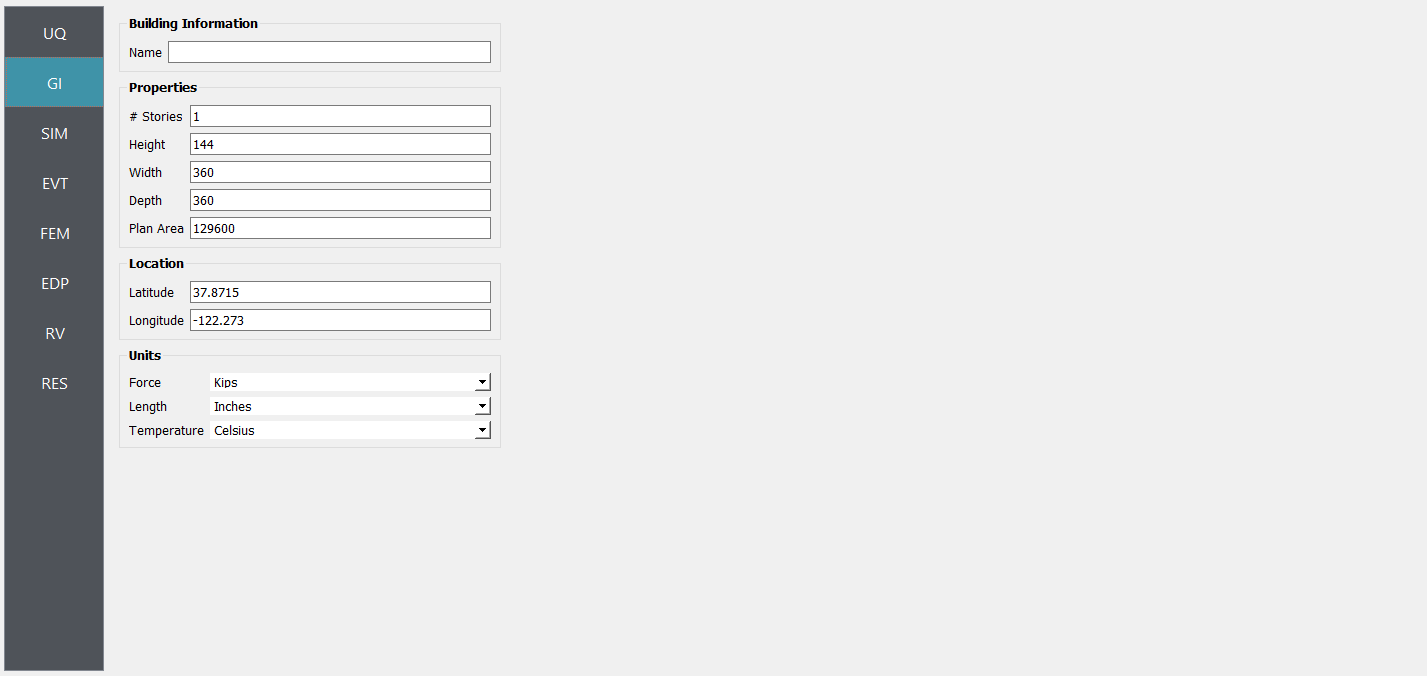

2. Next select the GI panel. In this panel, the building properties and units are set. For this example enter 1 for the number of stories, 144 for building height, 360 for building width, and 360 for building depth.

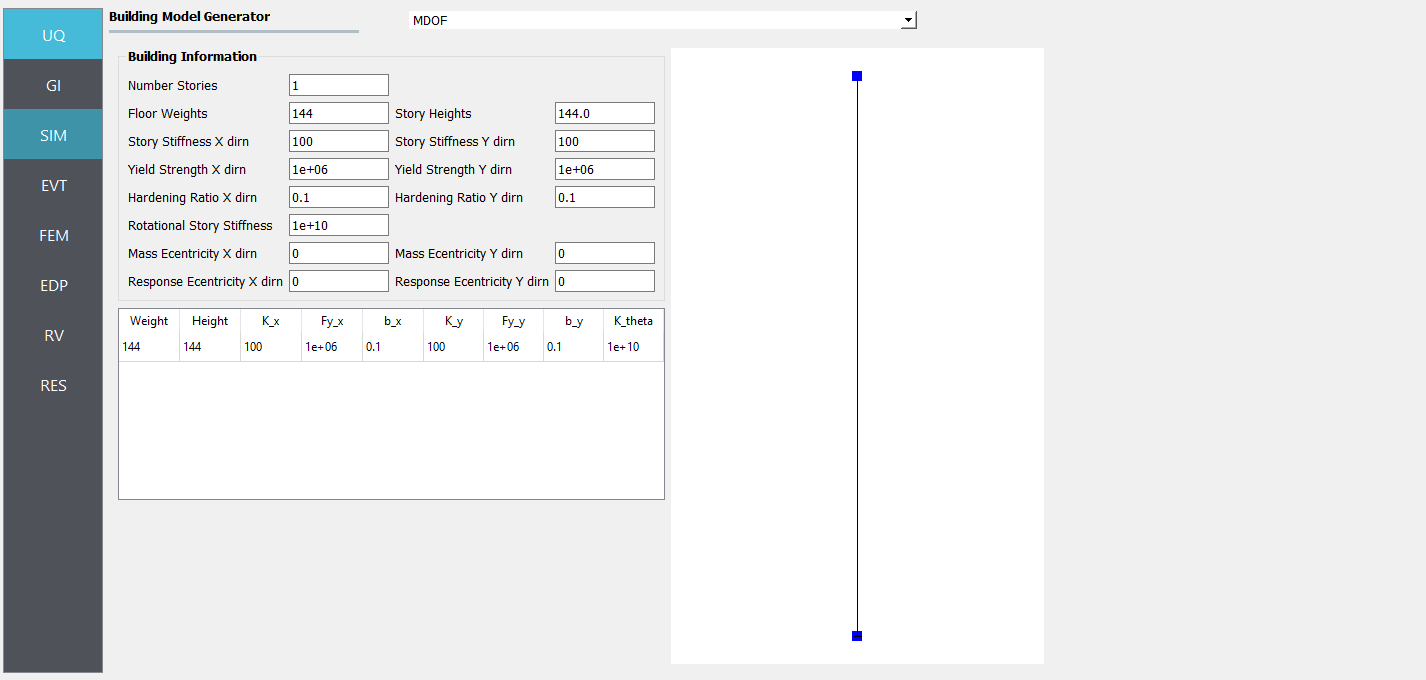

4. Next select the SIM tab from the input panel. This will default in the MDOF model generator. Define other input variables as shown in figure:

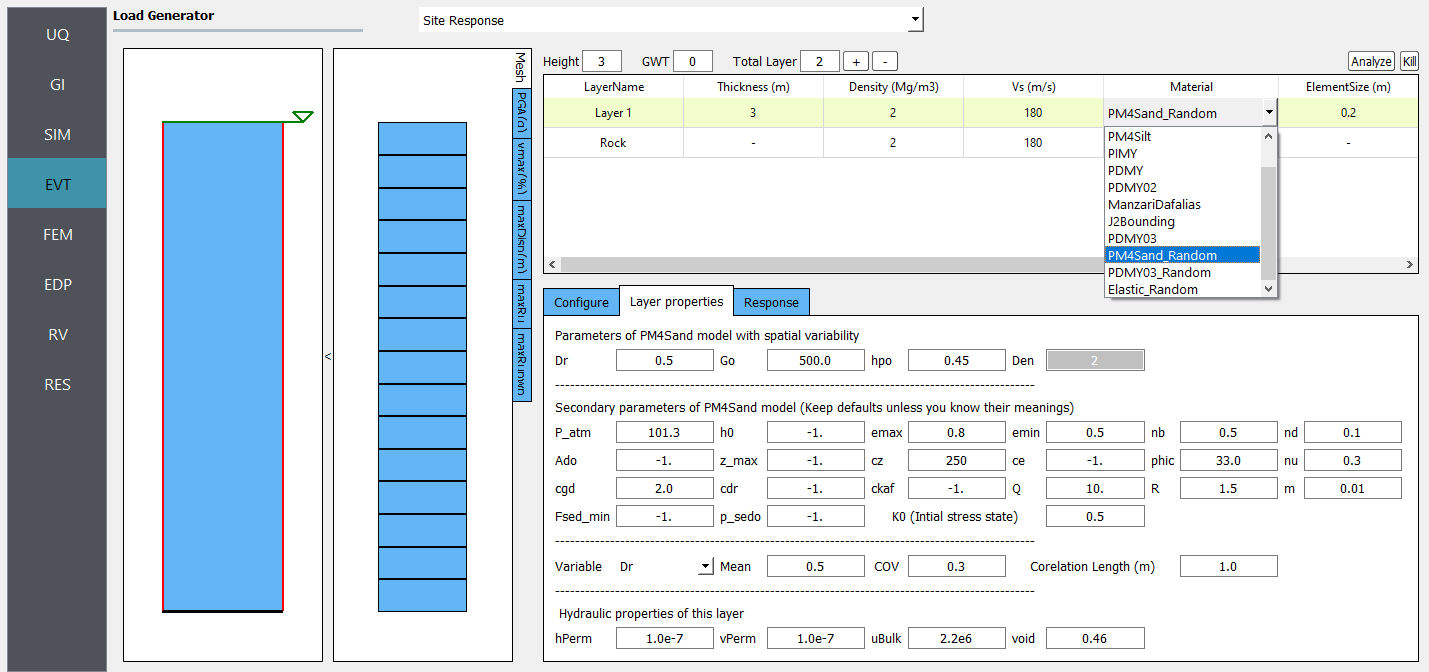

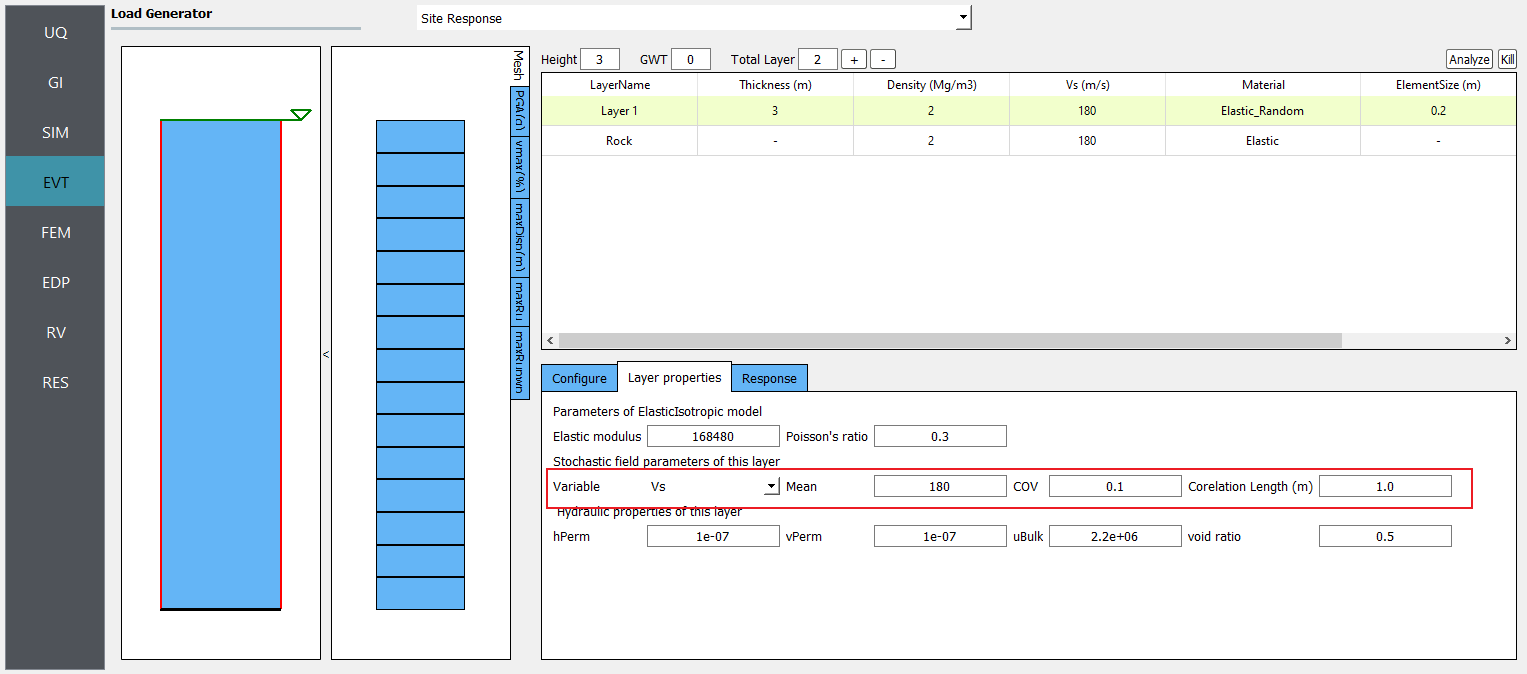

5. Next select the EVT panel. From the Load Generator pull-down menu select the Site Response option. Define soil profile, groundwater table (GWT), and mesh. Then select interested material, e.g., PM4Sand_Random, PDMY03_Random, or Elastic_Random. Under Configure tab, select the path to the input motion.

Note

A reasonable mesh resolution is recommended. Selection of element size should consider several factors, including but not limited to, layer shear wave velocity (for frequency resolution), correlation length (for random field resolution), and computation efficiency.

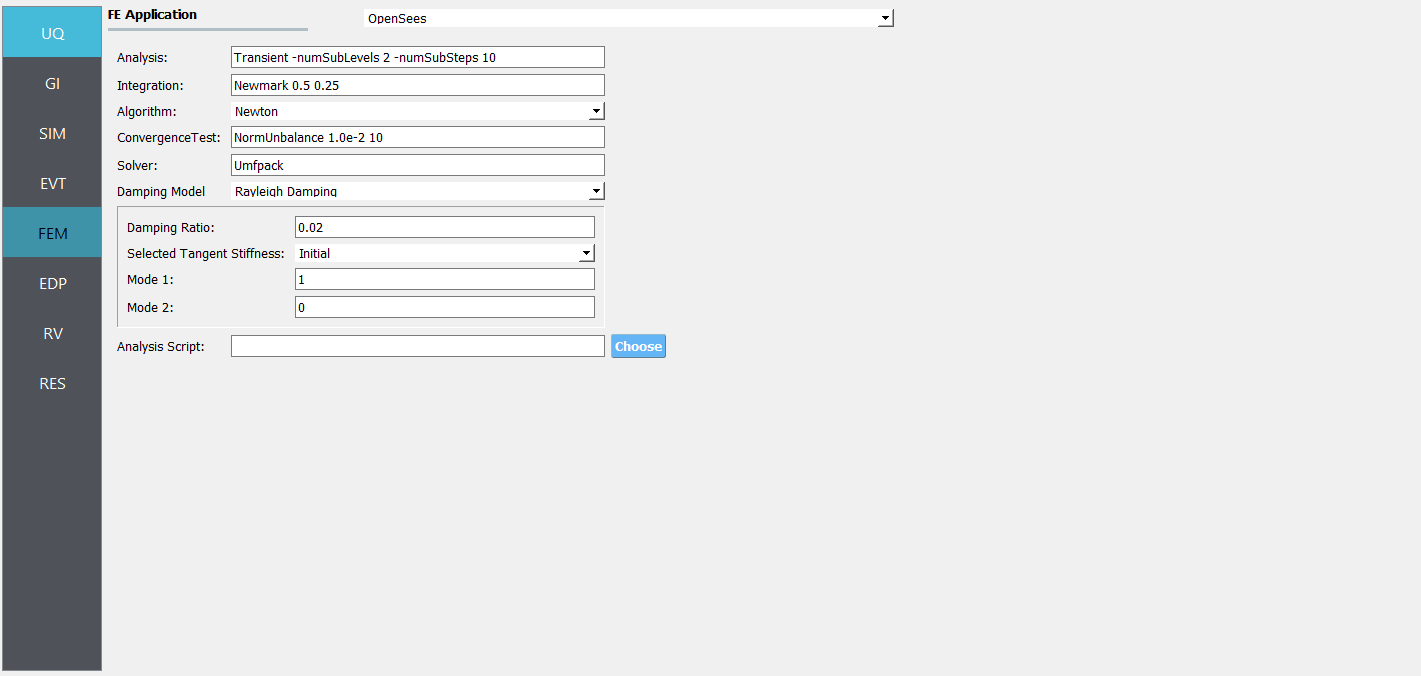

Next choose the FEM panel. Here we will change the entries to use Rayleigh damping, with the Rayleigh factor chosen using 1 mode.

We will skip the EDP panel leaving it in its default condition, that being to use the Standard Earthquake EDP generator.

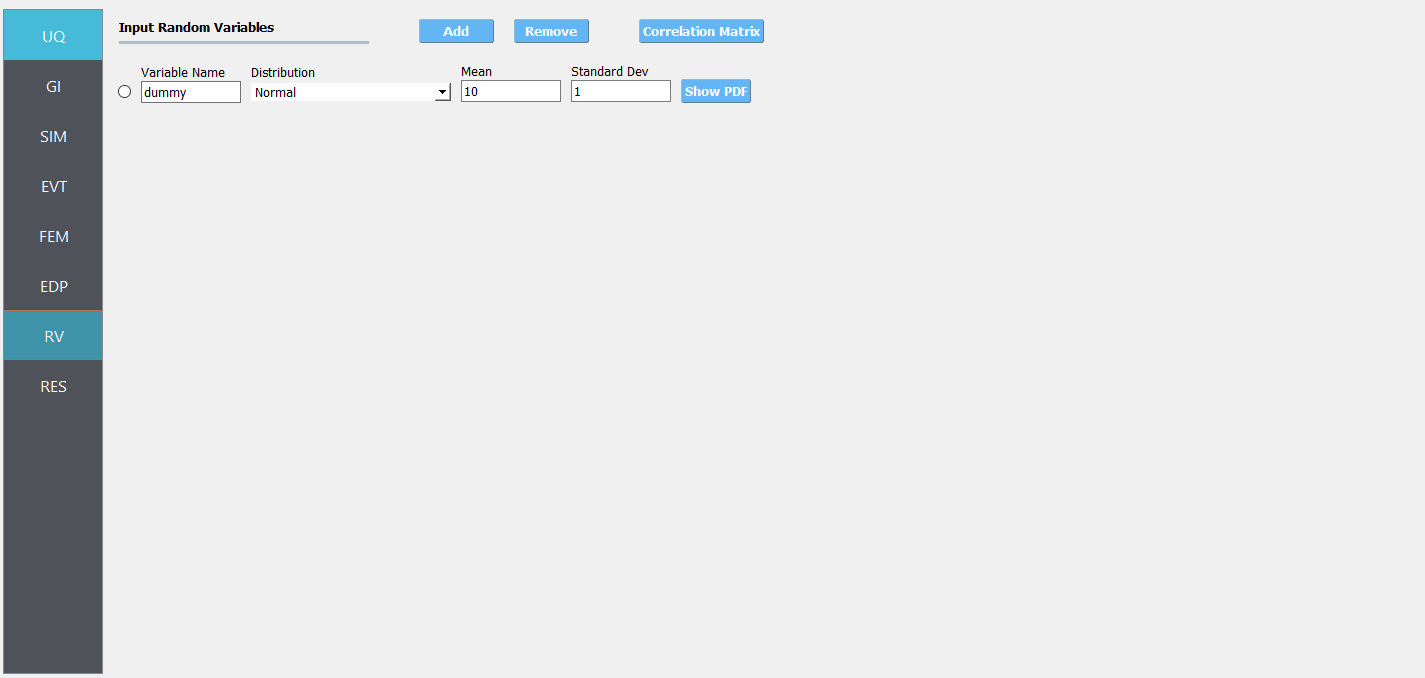

8. For the RV panel, we will enter the distributions and values for our random variables. If only the uncertainty related to spatial variability is of interest, a dummy random variable can be defined in this tab. Then all the variability shown in the response will solely be due to spatial variability in the site response analysis.

Warning

The user cannot leave any of the distributions for these values as constant for the Dakota UQ engine.

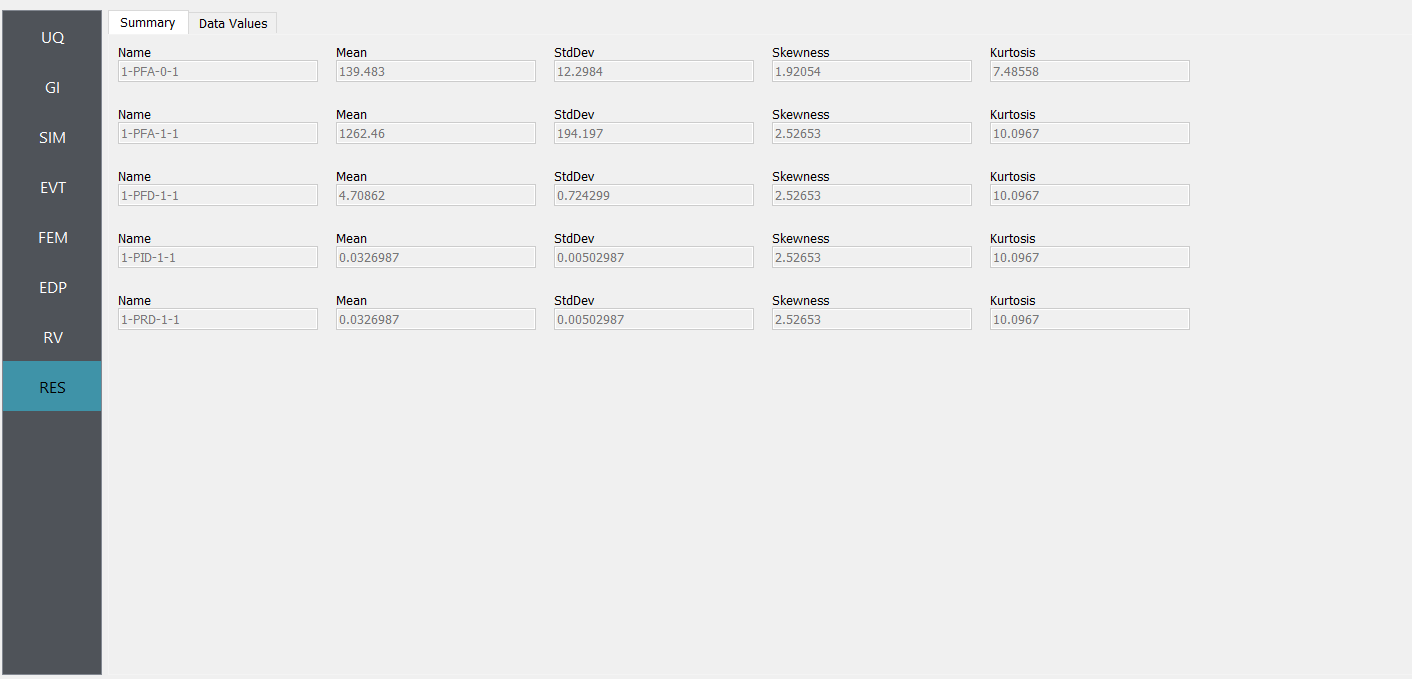

9. Next click on the ‘Run’ button. This will cause the backend application to launch dakota. When done the RES tab will be selected and the results will be displayed. The results show the values of the mean and standard deviation. The peak displacement of the roof is the quantity PFD. The PFA and PFD quantity defines peak floor acceleration and displacement, respectively, and the PID quantity corresponds to peak inter-story drift.

4.2.3. Adding Spatial Variability

4.2.3.1. Case 1: using ElasticIsotropic material

For the Elastic_Random material, shear wave velocity (Vs) can be selected to be randomized. Then select the Mean and COV (coefficient of variation \(=\frac{\sigma}{\mu}\)) for shear wave velocity. Correlation length defines how shear wave velocities are vertically correlated. Subsequently, Young’s modulus is calculated based on the stochastic shear velocity profile at the center of each element. No special calibration is required.

Note

Vs is bounded between 50 and 1500 m/s. These limits can be modified in calibration.py.

Fig. 4.2.3.1.1 Define inputs for Elastic_Random material.

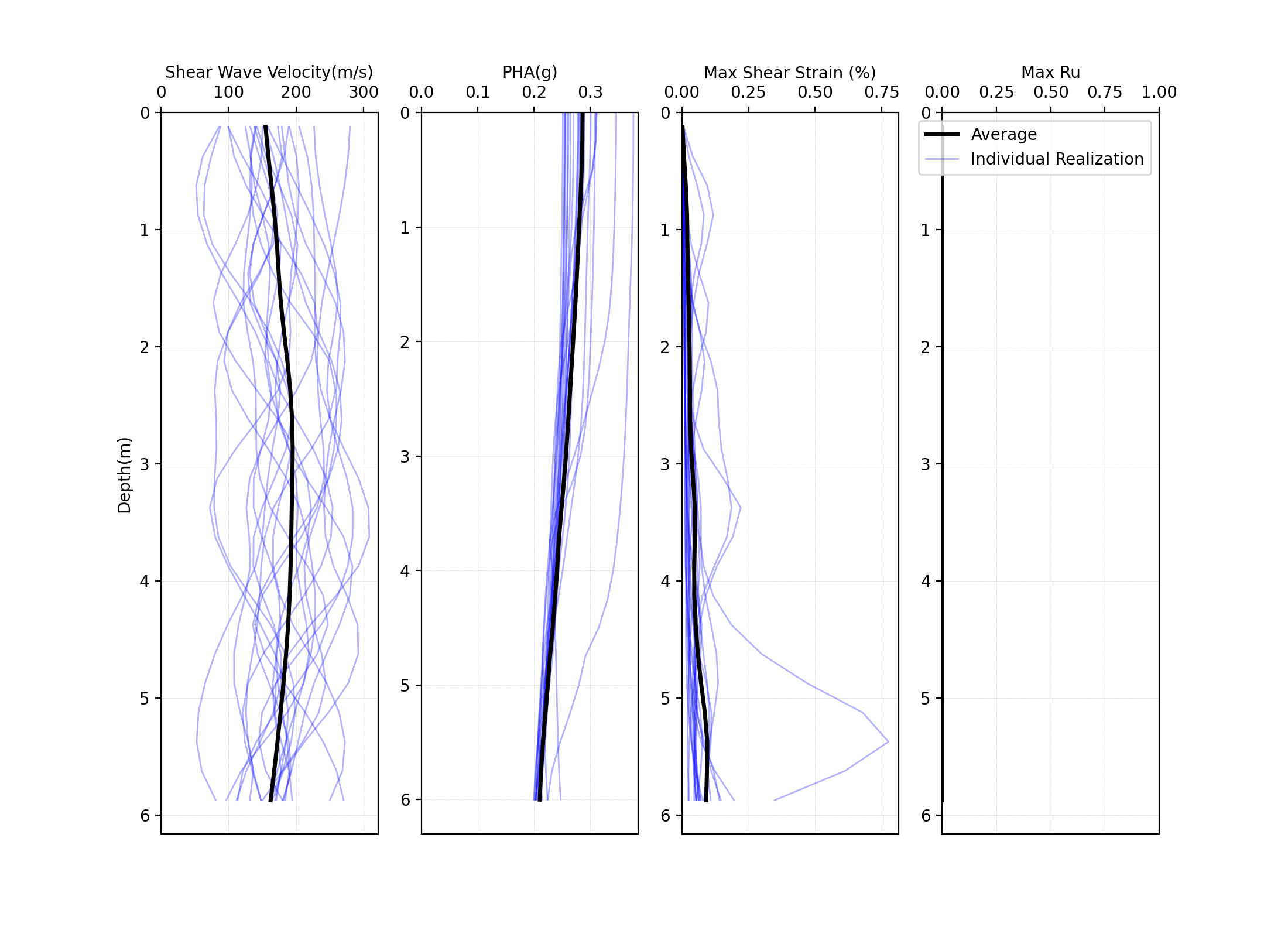

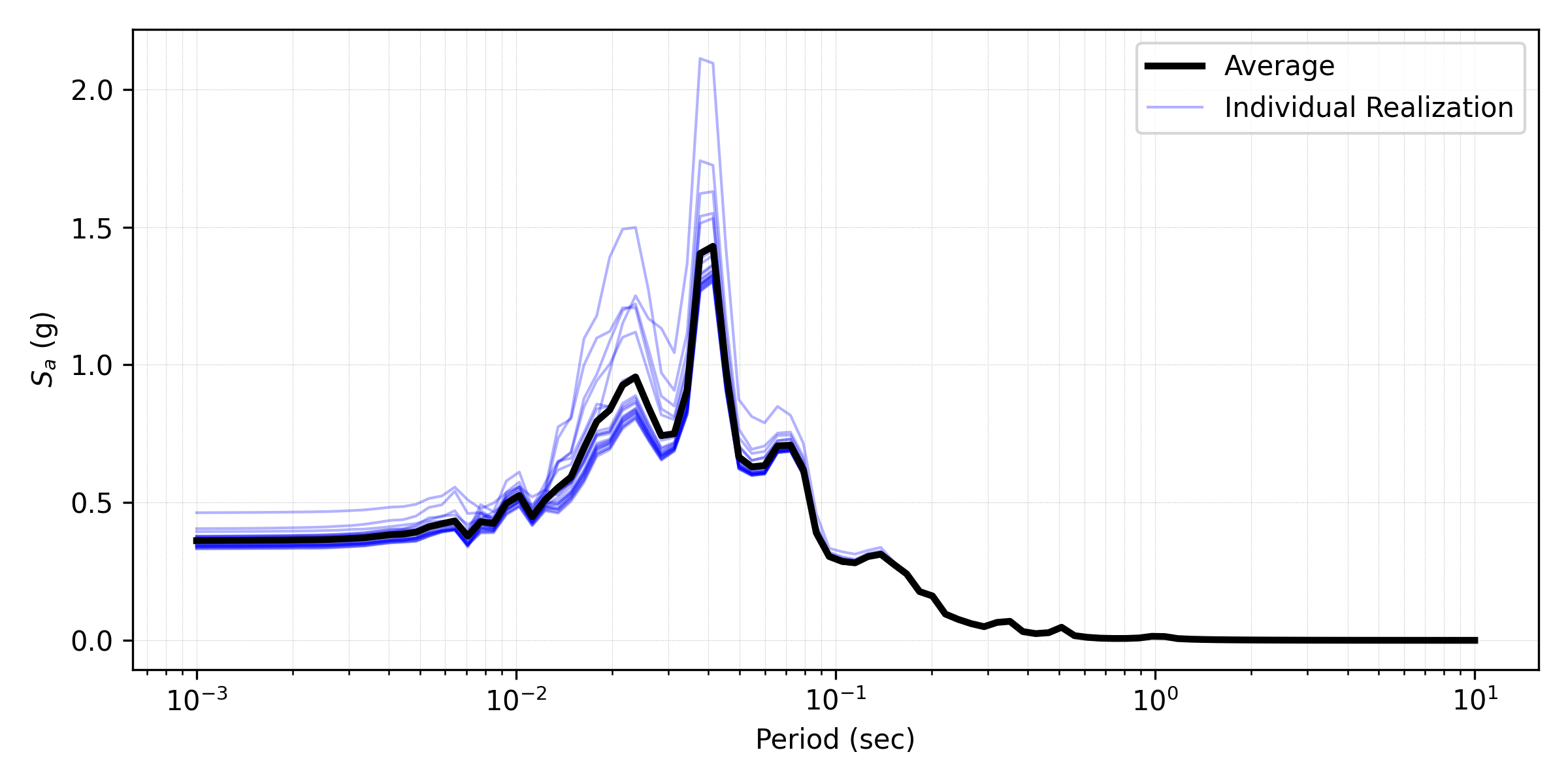

The below image presents the profiles of shear wave velocity, peak horizontal acceleration, maximum shear strain, and maximum excess pore pressure ratio (Ru) obtained from 20 realizations. Ru is always zero since there is no volumetric strain in ElasticIsotropic material. It shows the mean and each individual response spectra (5% damping) at the surface were obtained from 20 realizations.

Fig. 4.2.3.1.2 Profiles of shear wave velocity, peak horizontal acceleration, maximum shear strain, and maximum excess pore pressure ratio (Ru) were obtained from 20 realizations (postprocessed from realization output data).

Fig. 4.2.3.1.3 Response spectra (5% damping) at the surface obtained from 20 realizations (postprocessed from realization output data).

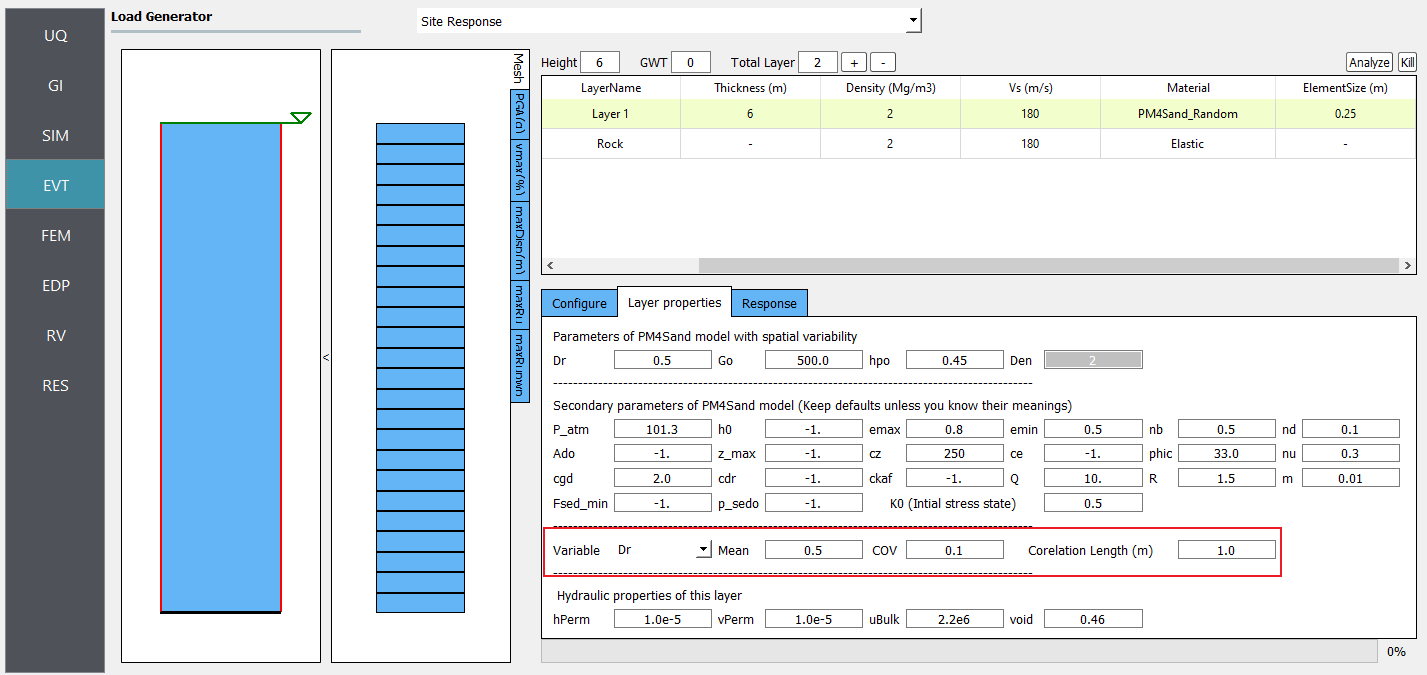

4.2.3.2. Case 2: using PM4Sand material

For the PM4Sand_Random material, relative density (Dr) can be selected to be randomized. Then select the Mean and COV (coefficient of variation \(COV=\frac{\sigma}{\mu}\)) for shear wave velocity. Correlation length defines how shear wave velocities are vertically correlated. In the current calibration procedure, all the other parameters are kept as input except for the contraction rate parameter hpo, which is calibrated based on the empirical triggering model proposed by Idriss and Boulanger 2008.

Fig. 4.2.3.2.1 Define inputs for PM4Sand_Random material.

Note

Dr is bounded between 0.2 and 0.95. These limits can be modified in calibration.py.

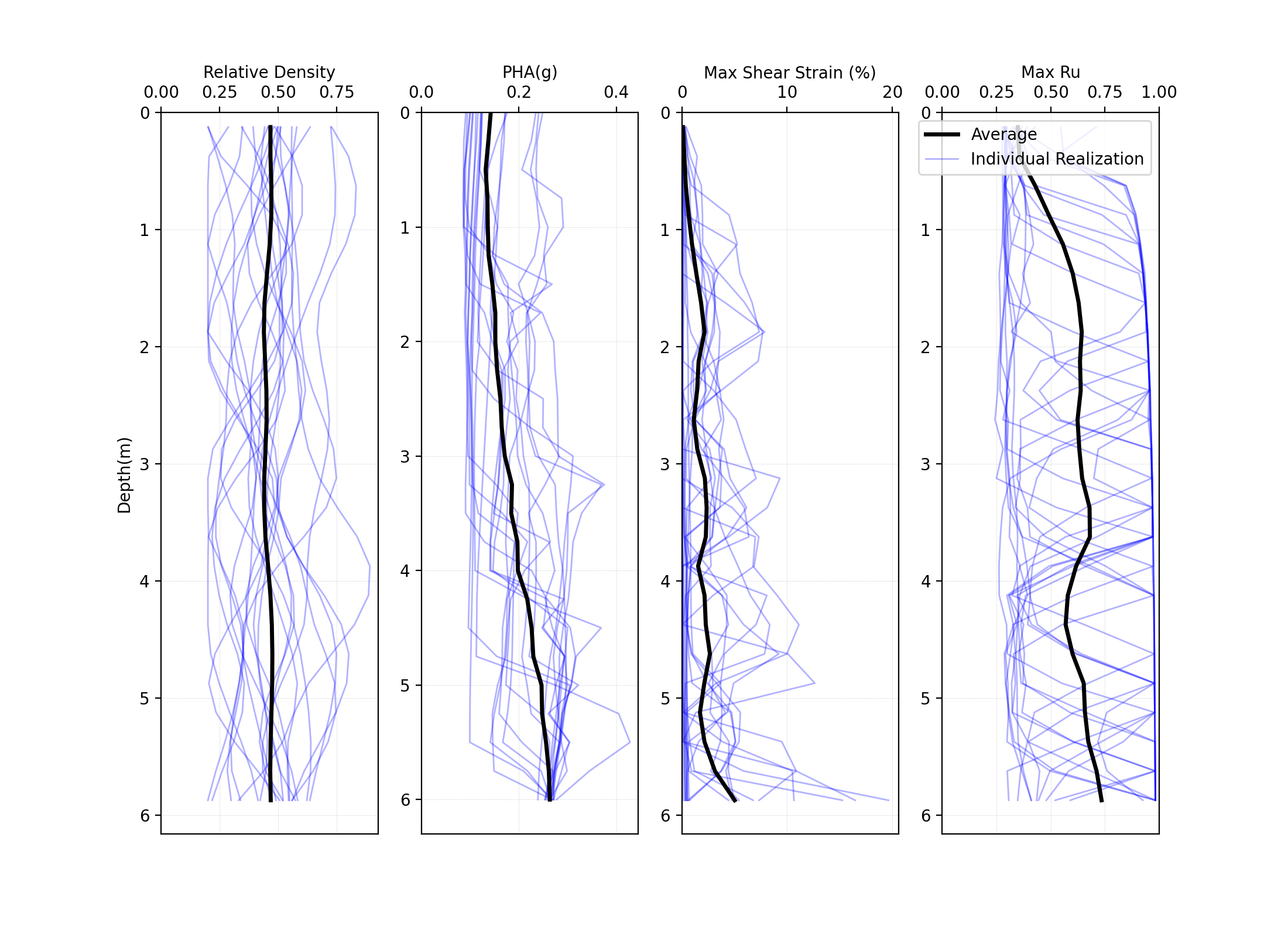

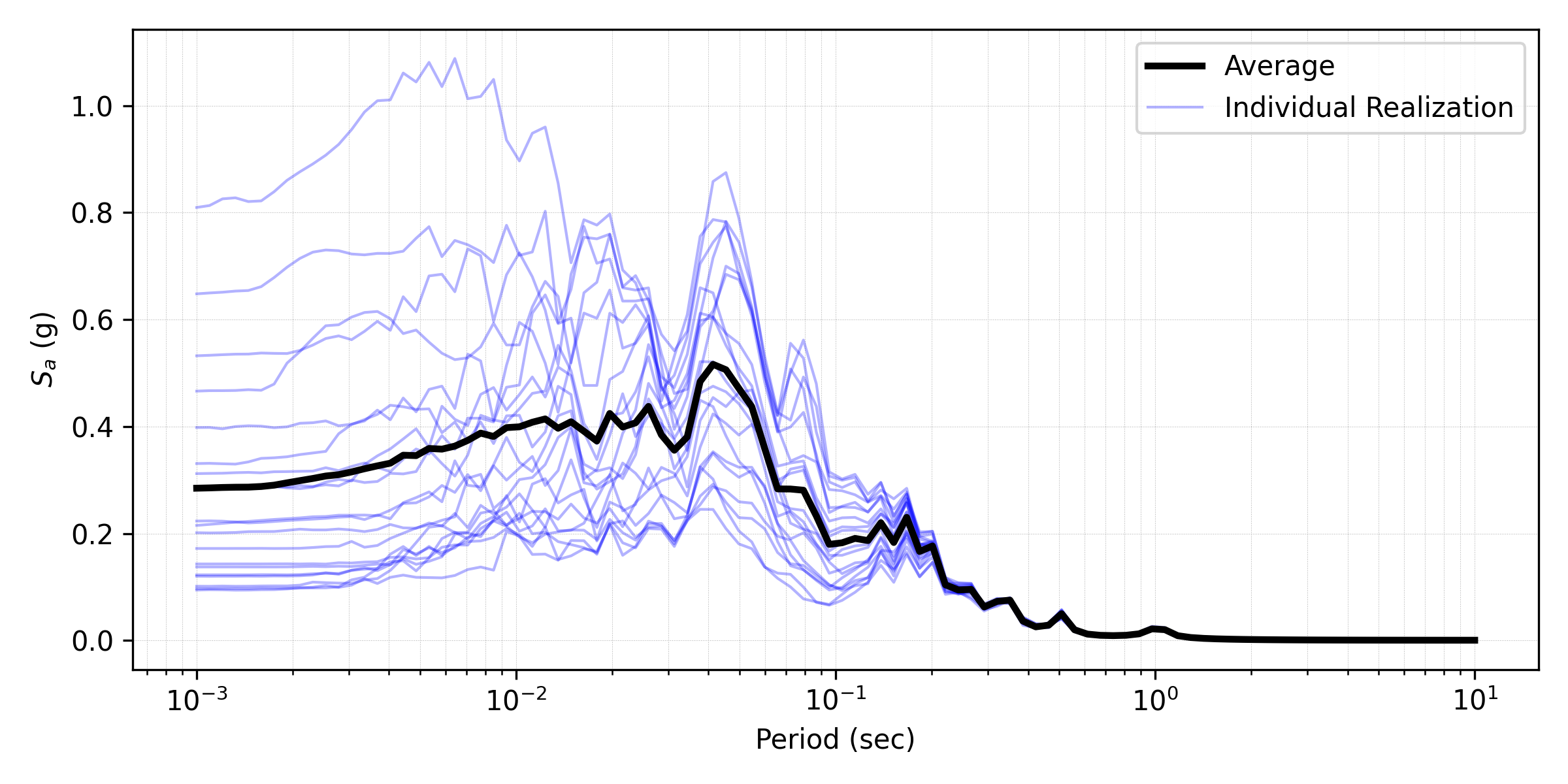

The below image presents the profiles of shear wave velocity, peak horizontal acceleration, maximum shear strain, and maximum excess pore pressure ratio (Ru) obtained from 20 realizations. Compared to elastic material, more variability is shown among these realizations. It depicts the mean and each individual response spectra (5% damping) at the surface obtained from 20 realizations.

Fig. 4.2.3.2.2 Profiles of shear wave velocity, peak horizontal acceleration, maximum shear strain, and maximum excess pore pressure ratio (Ru) were obtained from 20 realizations (postprocessed from realization output data).

Fig. 4.2.3.2.3 Response spectra (5% damping) at the surface obtained from 20 realizations (postprocessed from realization output data).